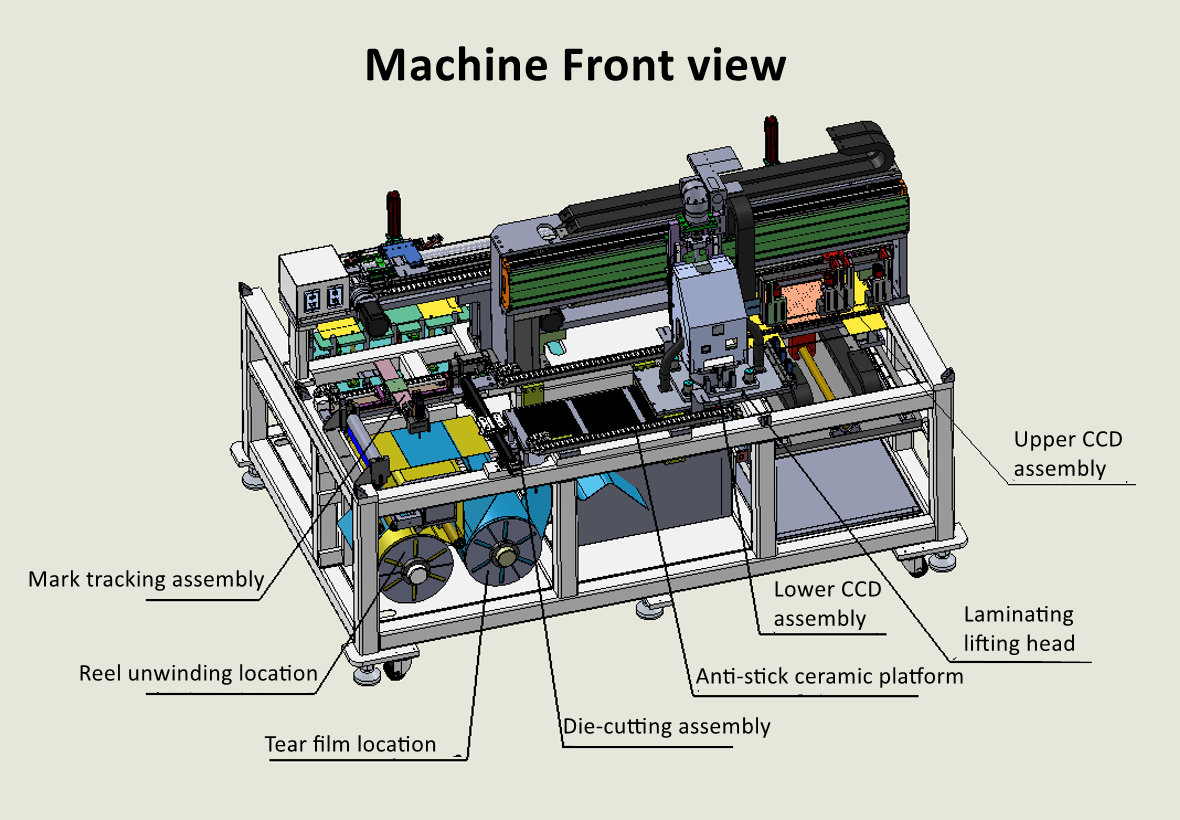

Automated CCD Sheet to Roll Laminator – High Speed, High Precision, Easy Operation

Introduction

In modern manufacturing, speed and accuracy are critical. The Automated CCD Sheet to Roll Laminator is built to meet these needs. It uses CCD cameras to guide each lamination with great accuracy. This machine helps save time, reduce waste, and improve product quality.

If your business involves touch panels, films, nameplates, solar energy products, or electronics, this machine can help improve your production process.

What is a Sheet to Roll Laminator?

A sheet to roll laminator sticks flat sheets onto roll materials. It is often used in high-tech industries. It helps companies save labor, reduce errors, and keep their product standards high.

The CCD version of this laminator includes a vision system. It uses cameras to find the correct position of the sheet. It then adjusts the sheet before lamination, ensuring perfect alignment every time.

Key Features

✅ 1. CCD Visual Positioning System

Built-in CCD cameras detect sheet edges or marks.

The machine adjusts the position in real time.

High accuracy reduces human error.

Perfect for sensitive products like displays or optical films.

✅ 2. Automatic Feeding and Laminating

Sheets are picked up and placed by the machine.

Lamination is done automatically.

No need for manual operation.

Great for long production runs.

✅ 3. High Precision and Speed

The machine runs fast while keeping high accuracy.

Controlled by servo motors and PLC systems.

Produces consistent results.

Reduces defects and waste.

✅ 4. Touchscreen Control

Easy-to-use interface.

Set speed, pressure, and alignment with a few taps.

Operators can learn quickly.

Supports custom settings for different jobs.

✅ 5. Works with Many Materials

Handles PET, PC, PMMA, and other sheets.

Laminates onto OCA, protective film, glue film, etc.

Supports different sizes and thicknesses.

✅ 6. Strong Build, Long Life

Uses strong steel and aluminum.

Designed for 24/7 use.

Easy to clean and maintain.

Where This Machine is Used

This laminator is used in many industries. It helps companies make products that are clean, aligned, and high in quality.

📌 Electronics

Used for screen displays, mobile phone parts, and PCBs. The precise lamination avoids dust and bubbles.

📌 Automotive

Helps produce dashboards, panels, and film decorations. Clean finish and good bonding are key.

📌 Solar Energy

Used in solar panel film layering. Needs perfect fit and no bubbles for best performance.

📌 Printing and Packaging

Nameplates, labels, and decals can be laminated quickly. The final product looks sharp and clean.

📌 Optical Films

Needed for clear, distortion-free lamination. CCD control ensures perfect placement.

Why CCD Technology Matters

CCD stands for Charge-Coupled Device. It’s a type of camera that can detect very small changes. In this machine, CCD cameras help align the sheet correctly before pressing it onto the film.

Without this, sheets can shift or tilt, causing waste. With CCD, you get perfect alignment every time.

Benefits to Your Business

💡 Lower Labor Costs

The machine works automatically. You don’t need many people to operate it.

💡 Better Product Quality

Sheets are always placed in the correct spot. That means fewer returns and complaints.

💡 Less Material Waste

No need to throw away parts due to misalignment. This saves money over time.

💡 Faster Production

You can run the machine for long hours. It’s made for high-volume jobs.

💡 Simple Operation

New workers can learn it fast. No special training is needed.

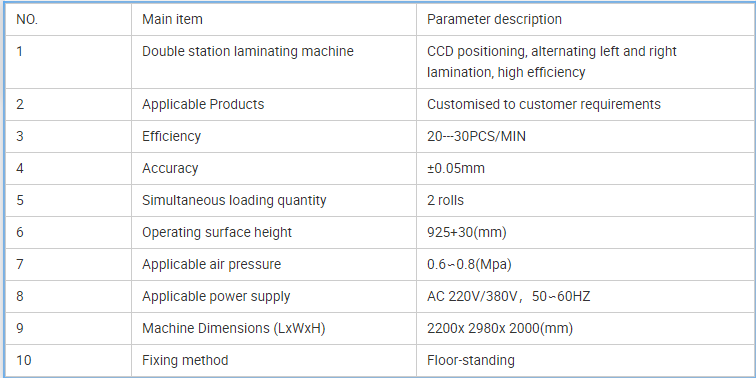

Technical Specs Overview

| Feature | Description |

|---|---|

| Sheet Size Range | Customizable (e.g., 100mm–600mm) |

| Roll Material Width | Up to 1000mm |

| Laminating Speed | Up to 25 m/min |

| Alignment Accuracy | ±0.1mm (depends on camera setting) |

| Control System | PLC + Touchscreen HMI |

| Drive System | Servo Motor |

| CCD Camera Type | Industrial-grade HD CCD |

| Feeding Style | Automatic sheet feeder |

| Power Supply | 220V/380V, 50/60Hz |

| Machine Size | Depends on model – usually 2.5–3.5 meters |

Note: Specs can be customized according to needs.

SEO-Friendly Keywords to Target

We have included top SEO keywords to help your page rank better. Here are some relevant ones:

automated sheet to roll laminator

CCD alignment laminating machine

high precision sheet lamination

automatic laminator for PET sheet

OCA film laminating system

visual positioning laminator

servo-controlled lamination machine

industrial laminating equipment

smart laminating machine

lamination machine for solar film

Using these keywords in your product page, blogs, and ads can help bring more traffic and leads.

Global Use Case

Our laminators are used in:

Germany – For car display panels

South Korea – For mobile touchscreens

India – For electronics and signage

Mexico – For solar film production

Thailand – For smart home device parts

USA – For packaging labels and branding

Our machines run smoothly in more than 30 countries. Many customers buy again after their first order. We also support OEM and ODM services.

Installation and Support

We offer:

Online and on-site training

Fast delivery and setup help

1-year warranty (extendable)

Spare parts in stock

Remote troubleshooting via video call

How to Order

Ordering is easy:

Tell us what material you laminate.

Share your sheet size and roll width.

Choose the model that fits your need.

We give you a clear quote and delivery time.

Confirm and we start production.

We pack the machine well and ship worldwide.

Conclusion: A Smart Investment

The Automated CCD Sheet to Roll Laminator is not just a machine. It’s a solution that helps your business grow.

Want faster output? ✔

Want better quality? ✔

Want less waste? ✔

Want easier operation? ✔

Then this is the right machine for you.

Contact Us Now

📩 Want a free consultation or quote?

📞 Reach out to our team today.

🌍 We support clients worldwide.

Let’s upgrade your factory together.

laminating machine

Unlike traditional laminators, CCD-guided systems visually register each sheet before lamination, eliminating human error and improving yield rates.